We want to help you achieve your goals of having a flooring solution that will last for the lifetime of your auto dealership.

By combining advanced tile installation techniques with the strongest floor tile available, we’re able to deliver a permanent flooring solution for our clients nationwide. From vibrated flooring systems to traditional thinset applications, we turn your vision for your dealership into reality.

Vibrated flooring systems. An automobile service shop takes on a lot over its lifetime – heavy equipment, dropped car parts and tools, as well as oil, water and other lubricants. For dealership owners that are looking to get the most durability out of their shop floor, a vibrated floor with clinker tile is the premiere option. These highly-specialized flooring systems are most often seen with new construction, and we can bond directly to the slab or indirectly through the use of a separation layer. Keep reading »

Thin set applications. For dealerships that may be going through an upfit or experiencing failure with their current flooring system, our clinker tile floors installed via thinset are an appropriate choice. With the right mix of slab restoration and floor leveling, our experts are able to make your original concrete slab new and functional again. Keep reading »

Polished & Stained. Polished and stained concrete flooring is a fashionable, economical flooring design process. Easy to maintain floor with mirror like shine, it combines the luxurious appeal of high-end stone with the durability of concrete. With a wide variety of concrete stain colors to choose from, and multiple levels of potential polished sheen, your stained and polished concrete flooring is sure to stand out. Keep reading »

Sealed. Sealed concrete is an economical solution that allows you to protect your concrete slab without all of the steps required in polishing. The level of finish will depend on the condition of the concrete as well as the customers’ expectations. A seal is created by densifying the concrete, which hardens and dust proofs the concrete surface by creating a chemical reaction with the free lime in the concrete.

Epoxy. Is a poured in place, durable floor system that can be used across a broad spectrum of industries. Epoxy coating is chemically resistant, durable, and a low maintenance product. Quick installation means less production shutdown and slippage. Keep reading »

Urethane. Urethane mortar flooring is a resinous flooring that like epoxy and MMA flooring is an applied concrete coating. Similar to epoxy and MMA flooring, urethane mortar, also known as urethane concrete or cementitious urethane, produces a seamless resinous flooring solution. Keep reading »

MMA. Methyl Methacrylate (MMA) flooring like epoxy flooring provides a seamless, resinous flooring solution that mimic the epoxy flooring benefits but under harsher enviromental conditions. Keep reading »

Leveling and screeding. Leveling the floor surface is the final step in preparing your subfloor for a new flooring installation. Keep reading »

Removal. Sometimes the floor removal is the first step in our concrete surface preparation process. This is particularly true of resinous flooring systems that need a clean and textured surface to properly bond. Keep reading »

Surface restoration of existing concrete floors is a necessary part of new seamless floor installation, and may be combined with removal, grinding, moisture mitigation, or self-leveling to appropriately prepare your subfloor for installation.

Shot Blasting is the most important step in preparing the surface for a new seamless floor, removes old floor coatings and the contaminants within the top surface layer. Keep reading »

Grinding cleans the concrete surface by removing a small layer of material. It flattens and smooths surfaces, levels out high spots, removes coatings, mastics, epoxies, urethane, adhesive residue and paint. Keep reading »

Moisture testing and mitigation. MVT problems can attack impervious and permeable flooring materials including wood, vinyl, tile, urethane, epoxy, and carpet. Often the end result is disbondment, blistering, pinholes, chipping and pitting, adhesive reversion, and cracking and heaving. If left untreated it can introduce health concerns associated with Sick Building Syndrome – by aiding the growth of algae, bacteria, mildew, and mold, as well as inducing rot. Keep reading »

Tile. A classic and durable option, tile is not only beautiful but is often the most economical option for long-term installations as well. Whether a traditional or modern look is desired, limitless style options mean that nearly any vision is possible. An additional combination of Eco-friendliness and minimal maintenance really make tile a stand-out option for any installation.

Ceramic. Beautiful and durable, ceramic tiles are environmentally friendly, economical, low maintenance, allergen reducing, and easily repairable. Ceramic tiles are manufactured using natural, water-resistant materials making them a natural, high-quality addition to any space from backsplashes to bathrooms to walls and foyers.

Porcelain. While similar to ceramic tiles, porcelain tile is typically a harder but more brittle tile. Choosing between the two is often a choice of taste.

Carpet Installation. A soft and quiet choice, carpet is found in lots of spaces that benefit from its soft and warm tone. Often paired with other flooring installations, carpet has many benefits.

Wool. Appealing for how it features a series of carefully woven fibers that resist dirt and stains.

Polyester. A prominent synthetic material, polyester resists moisture and stains, and is easy to clean.

Olefin. Originally used in outdoor situations due to its moisture resistance but increasingly found in indoor situations.

Nylon. Popular for its strength and durability.

Natural stone. This durable and attractive option that is also environmentally friendly. Natural stone is great value due to its uniqueness and low maintenance. With the numerous choices available, natural stone can be an excellent choice for many different projects.

start a project

Global Tiling works hard for our clients. We take individual needs and taylor our services to provide top-notch support. We recognize that each business is different and we are versatile enough to meet the needs of any business.

start a projectWe are pleased to work with a variety of Business Owners, General Contractors, Educational Institutions, Industrial Facilities, as well as others. We can provide time-saving, top-quality service to any business.

We provide services to numerous businesses in diverse settings. From commercial grocery chains like Aldi to educational institutions like Furman University, office buildings that house businesses like Hughes Development to manufacturing facilities used by companies such as Magna Drive, there is no end to the types of businesses we can help.

Trying to choose the right flooring solution for your project can be overwhelming. Then trying to decide on the right installer to correctly install it further complicates the matter. We understand that a lot goes into these decisions and isn’t something to be rushed into.

Our team of professionals can help guide you through this process and lead you to the perfect floor that best suits your needs. We understand the importance of maintaining and following a schedule in this industry, so we commit to you to show up every day with energy, focus and enthusiasm, working with a sense of urgency in order to meet deliverables and keep your project on track. We know you have a lot of other things to consider with your project – let us worry about all the flooring details, as it’s our goal to make each interaction and experience with us as seamless and painless as possible.

Our German-trained and certified tile installers have decades of experience installing tile in car dealerships, both via the thinset method and the vibration method.

We are one of the few installation companies in the US that can successfully install a vibrated flooring system. The vibration method is a highly-specialized installation process, one that our installers have spent years crafting and perfecting.

WMüller currently has over 100 employees, including field-based tile installers and support staff in our office in Charlotte. We’ve got you covered in all 48 continuous states.

Our Project Management team makes preconstruction visits to each jobsite in order to develop a staging and phasing plan with the Superintendent. Once the project starts, they are in constant contact with our crew, and by directly managing this process we are able to better control costs, while also maintaining quality and increasing efficiency.

We work seamlessly with architects, designers, contractors, and business owners to deliver superior results to every project that bears the Müller name. How can we help you?

Vibrated flooring systems. An automobile service shop takes on a lot over its lifetime – heavy equipment, dropped car parts and tools, as well as oil, water and other lubricants. For dealership owners that are looking to get the most durability out of their shop floor, a vibrated floor with clinker tile is the premiere option. These highly-specialized flooring systems are most often seen with new construction, and we can bond directly to the slab or indirectly through the use of a separation layer. Our highly-skilled craftsmen will ensure you will get a truly flat flooring surface, one that will be most equipped to withstand all of the rigors of a service shop.

start a project

Thin set applications. For dealerships that may be going through an upfit or experiencing failure with their current flooring system, our clinker tile floors installed via thinset are an appropriate choice. With the right mix of slab restoration and floor leveling, our experts are able to make your original concrete slab new and functional again.

This installation method is also utilized for installing tile in the front of house locations of the dealership: showroom, lounge, restrooms and other customer-facing areas. Let our certified installers help bring your building to life!

start a project

Polished & Stained. Polished and stained concrete flooring is a fashionable, economical flooring design process. Easy to maintain floor with mirror like shine, it combines the luxurious appeal of high-end stone with the durability of concrete. With a wide variety of concrete stain colors to choose from, and multiple levels of potential polished sheen, your stained and polished concrete flooring is sure to stand out. It contains no volatile organic compounds (VOCs) so is an environmentally friendly option that is tough enough to withstand anything from foot traffic to forklift trucks.

start a project

Epoxy is a poured in place, durable floor system that can be used across a broad spectrum of industries. Epoxy coating is chemically resistant, durable, and a low maintenance product. Quick installation means less production shutdown and slippage. It's temperature, impact, and even fire resistant, making it a great safety choice. Available in an array of colors and patterns to fit nearly any style, epoxy is also a green choice due to its small material usage.

start a project

Urethane mortar flooring is a resinous flooring that like epoxy and MMA flooring is an applied concrete coating. Similar to epoxy and MMA flooring, urethane mortar, also known as urethane concrete or cementitious urethane, produces a seamless resinous flooring solution.

Urethane mortar coating provides a nonporous, easily cleanable surface that discourages bacteria and microbial growth. It works particularly well in areas that experience extreme temperature fluctuations or that must stay either cold or hot for long periods of time like refrigerated areas, freezer areas, or hot food processing areas. Because its thermal coefficient is similar to that of concrete, it manages thermal shock with higher degrees of stability and can withstand temperatures of up to 250°F. It is non-toxic and low VOC, making it nicely suited for food processing, clean rooms, or other areas where liquid containment and harsh temperatures put a strain on flooring surfaces.

start a project

Methyl Methacrylate (MMA) flooring like epoxy flooring provides a seamless, resinous flooring solution that mimic the epoxy flooring benefits but under harsher enviromental conditions

Like epoxy flooring, MMA flooring provides a seamless, resinous flooring solution. Unlike epoxy, Methyl Methacrylate is able to cure at extreme low temperatures in an exceptionally short amount of time – in about an hour, to enable almost immediate use or re-occupation of the space.

MMA flooring is weather resistant, making it an exceptional option for outdoor use, or indoors for pharmaceutical manufacturing, or food and beverage processing facilities like breweries.

MMA flooring is a strong abrasion resistant, chemical resistant, non-slip floor coating that protects floors and holds up to high foot traffic and heavy loads.

It is available in a solid finish, flake flooring (aka chip flooring) or quartz flooring to meet the look and texture your space industrial or commercial space demands. It is available in a variety of colors, chip sizes, and textures.

start a project

Leveling and screeding. Leveling the floor surface is the final step in preparing your subfloor for a new flooring installation.

It creates the final flat surface on which we install our flooring systems for an even base. It can also be used to pitch a floor toward a drain or patch inconsistencies.

Creating a level surface for flooring installation helps prevent future splitting, cracking, and chipping.

When needed removal, grinding, shot blasting and moisture mitigation services are also available as part of our full-service floor contracting capabilities.

start a project

Removal. Sometimes the floor removal is often the first step in our concrete surface preparation process. This is particularly true of resinous flooring systems that need a clean and textured surface to properly bond.

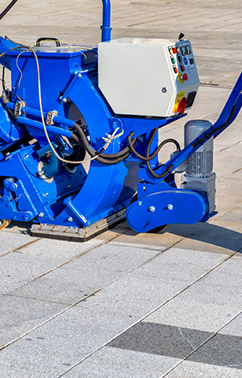

We operate two industrial floor scrapers/floor removal machines:

These remarkable machines enable us to remove all types of flooring systems including carpet, tile, rubber, VCT, LVT, wood, epoxy, MMA and urethane mortar. They save an enormous amount of labor time on demolition, helping to keep your job on schedule.

As part of being a full-service flooring contractor we can also offer shot blasting, grinding, moisture mitigation, and self-leveling as needed.

start a project

Shot blasting is the most important step in preparing the surface for a new seamless floor, removes old floor coatings and the contaminants within the top surface layer.

This is especially true when the substrate is heavily damaged, deeply contaminated or has failing or inappropriate coatings for the intended usage.

We maintain a fleet of shot blasting machines and a trained team of experienced flooring professionals who are skilled in determining the correct size steel shot blast media to use to achieve the desired exposed surface area.

start a project

Grinding cleans the concrete surface by removing a small layer of material. It flattens and smooths surfaces, levels out high spots, removes coatings, mastics, epoxies, urethane, adhesive residue and paint.

Large floor grinding machines use multiple rotating discs to remove paints and concrete coatings and to create light texturing of the concrete surface in large, open areas. Like shot blasting, grinding increases the concrete surface profile to improve the bonding properties of a newly applied resinous flooring.

start a project

Moisture testing and mitigation. MVT problems can attack impervious and permeable flooring materials including wood, vinyl, tile, urethane, epoxy, and carpet. Often the end result is disbondment, blistering, pinholes, chipping and pitting, adhesive reversion, and cracking and heaving. If left untreated it can introduce health concerns associated with Sick Building Syndrome – by aiding the growth of algae, bacteria, mildew, and mold, as well as inducing rot.

Moisture Vapor Transmission (MVT) is the movement of water vapor from “high to low” concentrations as it attempts to reach equilibrium within its overall environment.

We test for MVT in accordance with ASTM F1869 (using Anhydrous Calcium Chloride) and ASTM F2170 (determining relative humidity).

We recommend a simple moisture test before installing any flooring, which can now be done in as little as 24 hours using Rapid RH tests from Wagner Meters testing for relative humidity in the slab, giving the most accurate results.

When excessive moisture is detected, we treat flooring surfaces with AC•Tech 2170 by Allied Construction Technologies. XXXX is an official distributor of AC•Tech 2170.

AC•Tech 2170® FC ZERO is a 2 component, 100% solids vapor reduction epoxy that contains ZERO VOCs and is fast curing, making it ideal for fast track construction. It is a true one-coat system that has been formulated to remain bonded to properly prepared concrete with high moisture levels and alkalinity loads. AC Tech ® 2170 FC ZERO withstands moisture levels as high as 100% RH (ASTM F2170) with no upper MVER limit (ASTM F1869) and is insensitive to sustained alkalinity as high as pH 14.

start a project